Test Liner

Priority

Testliner paper is a corrugated packaging paper often used in board production. It consists of a combination of recycled fibers and virgin fibers, with the recycled fiber content usually being higher.

The exact composition of testliner paper it consists of a mixture of recycled paper obtained from recycled cardboard, newspapers and other paper products, and virgin fibers obtained from wood. The combination of recycled fibers and virgin fibers gives testliner paper its specific properties.

Application

Die Anwendung von Testliner-Papier liegt hauptsächlich in der Verpackungsindustrie, insbesondere bei der Herstellung von Wellpappenkartons. Es wird als äußere Schicht oder als Deckenpapier auf den Wellenkartonlagen verwendet, um dem Karton zusätzliche Festigkeit, Steifigkeit und Druckbeständigkeit zu verleihen. Testliner-Papier kann auch für die Herstellung von Etiketten, Displays und anderen Verpackungsmaterialien eingesetzt werden.

Benefits

The benefit of testliner paper is that it provides a cost-effective option for packaging because it is made from recycled materials. It is also more environmentally friendly than paper made entirely from virgin fibers, as it reduces the consumption of natural resources and reduces waste disposal. In addition, testliner paper adds strength and protection to cartons to safeguard the products inside during shipping and storage.

Kraft Paper

Priority

Kraft paper is a robust and versatile paper made from wood pulp.

It is characterized by its high tensile strength, toughness and durability.

The exact composition of kraft paper it is made from long fibers of coniferous trees such as pine or spruce. The fibers are treated chemically or mechanically to achieve the desired properties. Kraft paper can be made from virgin fibers as well as recycled fibers. Brown kraft paper often uses unbleached fibers, while white kraft paper is bleached to achieve a lighter color.

Application

Kraft paper has a variety of applications. It is commonly used in the packaging industry, especially for products that require strength and durability, such as bags, pouches, boxes, envelopes and packaging materials. It is also used for labels, book covers, writing paper, craft projects and as a backing in various industries.

Benefits

The benefit of kraft paper lies in its outstanding properties. It is very tear resistant and strong, which makes it ideal for packaging heavy or delicate items. It also provides some barrier against moisture and grease, which increases the protection of packaged products. Kraft paper is recyclable and biodegradable, making it an environmentally friendly option. It is made from renewable resources and helps reduce waste. In addition, kraft paper can be printed, labeled or painted, making it a popular material for creative projects.

Baking paper

Priority

Baking paper, also known as parchment paper or baking paper, is a specially treated paper used for baking food. It has a smooth, non-stick surface and is heat resistant.

The exact composition of baking paper it consists of cellulose fibers coated with a thin layer of silicone. This silicone layer gives the paper its non-stick properties and allows food not to stick to it.

Application

The application of baking paper is mainly in baking and cooking. It is used to prevent dough, pastry, meat, fish and other foods from sticking to baking sheets, molds or grills. Baking paper can also be used as a separator between layers of food to prevent sticking. It facilitates the removal of baked or cooked food from the surface and makes cleaning easier as it does not leave any residue.

Benefits

The benefit of baking paper lies in its functionality and convenience. It facilitates baking, as it eliminates the need to grease baking pans or trays. It ensures even browning and prevents food from sticking to the surface. Baking paper is also heat resistant and can withstand high temperatures without burning or melting. It is also environmentally friendly as it is recyclable and provides an alternative to other non-stick coatings that may contain chemical ingredients.

Greaseproof Paper

Priority

Greaseproof paper, also known as greaseproof paper or greaseproof paper, is a specially treated paper stock that is resistant to grease and moisture. It is commonly used in the food packaging industry.

The exact composition of greaseproof paper can vary, but it is usually made from pulp fibers that have been given a special coating to create a barrier against grease, oil and moisture. This coating can be made of natural materials such as wax, kerosene or other greaseproof substances.

Application

The application of greaseproof paper is mainly in food packaging and catering. It is used to package greasy or oily foods such as French fries, fried chicken, burgers, sandwiches, baked goods and other foods. The grease-resistant paper creates a barrier that prevents the grease or moisture from the food from getting into the package or onto the consumer’s hands. It keeps food fresh and protects against soaking or smearing.

Benefits

The benefit of greaseproof paper is that it preserves the quality and presentation of greasy foods. It prevents grease from seeping into other foods or packaging and ensures clean and easy-to-handle food portions. The greaseproof paper is food safe, odorless and can safely come into contact with food. It also offers the advantage of being easily recyclable, resulting in an environmentally friendly option for food packaging.

Auto-Filterpapier

Priority

Car filter paper is a specially developed paper used in vehicles for filtration of air, oil and fuel. It plays an important role in cleaning and protecting vehicle engines from dirt particles and contaminants.

The exact composition of automotive filter paper may vary depending on the manufacturer and application. However, it is usually made of a combination of cellulose fibers and synthetic fibers such as polyester or polypropylene. The fibers are selected based on their filtration properties, mechanical strengths and resistances to the conditions encountered in the vehicle.

Application

The application of car filter paper is in various vehicle systems, including air filters, oil filters and fuel filters. In the air filter, the paper is used to filter suspended particles such as dust, pollen and other impurities from the intake air and protect the engine from damage. In the oil filter, the paper is used to filter dirt particles and deposits from the engine oil and extend the life of the engine. In the fuel filter, the paper is used to remove impurities and sediments from the fuel and protect the fuel injection systems.

Benefits

The benefit of car filter paper lies in its effectiveness in the filtration of pollutants and impurities. It efficiently removes particles and impurities in the air, oil and fuel that could otherwise cause damage to vehicle engines. The use of high quality filter paper increases the life of the engine and improves the performance and efficiency of the vehicle. Auto filter paper is tough and durable to withstand the stresses and vibrations in the vehicle. It is also chemically resistant to the fluids used in the vehicle systems and can maintain its filtration properties for an extended period of time.

Glassine Paper

Priority

Glassine paper is a highly transparent and smooth paper often used as release paper or protective layer in various applications. It is characterized by its special properties and composition.

The exact composition of glassine paper can vary, but it is usually made from pulp fibers that have been given a special chemical treatment. This treatment gives the paper its characteristic properties, such as high transparency, smoothness and grease resistance. In the traditional manufacturing process, the paper is produced by a drawing process, which tightly compresses the fibers and creates a smooth surface.

Application

The application of glassine paper is various. It is often used as a release paper in the food industry to separate food products such as confectionery, baked goods or cheese and prevent sticking. It is also used in the printing industry to protect delicate prints, illustrations or photographs. Glassine paper finds application as a protective layer for stickers, labels, packaging, archiving documents, artwork or stamps, as it provides a barrier against moisture and grease.

Benefits

The benefit of Glassine paper lies in its specific properties. The high transparency makes it possible to see the contents without removing the paper. The smoothness and grease-resistant properties prevent ink, paint or grease from penetrating or settling on the paper. It protects delicate surfaces from scratches or damage and serves as a protective layer for valuable or fragile items. In addition, Glassine paper is acid-free and age-resistant, making it a good choice for archival purposes to protect documents or artwork for the long term.

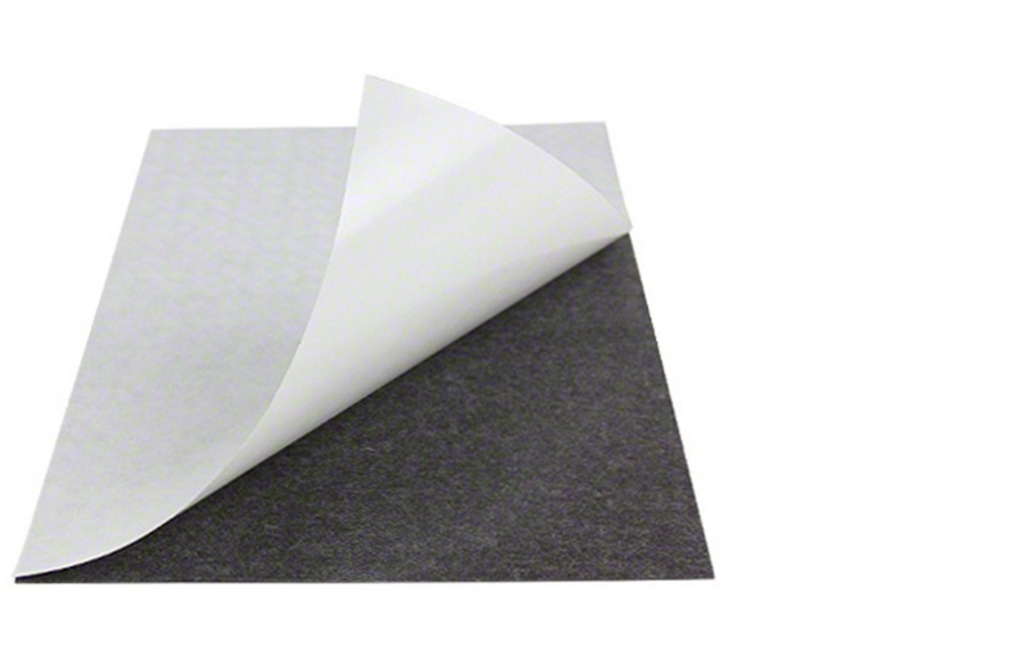

Self-Adhesive Paper

Priority

Self-Adhesive Paper, also known as self-adhesive paper, is a specially coated paper that contains a layer of adhesive on the back. It allows easy application to various surfaces without the use of additional adhesive or water.

The exact composition of self-adhesive paper can vary depending on the manufacturer and the application. Generally, it consists of a backing layer that stabilizes the paper and an adhesive layer that is applied to the back. The backing layer can be paper, plastic film or fabric. The adhesive layer is usually made of an acrylic adhesive or other adhesive material.

Application

The application of self-adhesive paper is diverse. It is widely used for labels, stickers, packaging materials, crafting, scrapbooking, posters, wall decorations and other decorative or functional purposes. It can adhere to various surfaces such as paper, cardboard, plastic, metal, glass and wood. Self-adhesive paper provides an easy and clean solution for attaching images, text or other designs to surfaces.

Benefits

The benefit of self-adhesive paper is its ease of use and versatility. It is easy to apply, as it does not require additional adhesives. It allows for quick and clean application of labels or decorations to various surfaces. Self-adhesive paper also offers flexibility as it can be easily peeled off and repositioned when needed. It is a practical solution for DIY projects, creative work and organizing items.

Thermal Paper

Priority

Thermal paper, also known as thermal printing paper or cash register roll paper, is a specially coated paper used in thermal printers. It reacts to heat, producing a visible representation of the print without the need for ink or ribbons.

The exact composition of thermal paper can vary, but it usually consists of three main components: the backing layer, the coating layer and the protective layer. The carrier layer is made of paper or plastic film and provides the base for printing. The coating layer contains a mixture of color developers, dyes and other chemical compounds that react to heat. The protective layer is located on top of the paper and protects the print from abrasion, smearing or fading.

Application

The application of thermal paper is mainly in receipt printing, such as point-of-sale systems, ATMs, parking machines, scales, ticket vending machines, and other devices that require instant print output. It is also used for receipts, tickets, admission tickets, labels, barcode labels and other types of short-lived printing applications.

Benefits

The benefit of thermal paper is its simplicity and speed of printing. It requires no ink, toner or ribbons, saving maintenance and costs. Thermal paper allows for a fast printing process and provides crisp and clear results. It also provides good legibility because the print appears directly on the surface of the paper without the need to absorb ink or toner. Thermal paper is also space efficient as it does not require additional supplies such as ribbons. However, it is important to note that printing on thermal paper can fade over time and is sensitive to heat, light and chemicals.

Tyvek

Priority

Tyvek is a high-strength, lightweight and water-resistant material consisting of fine, thermally fused fibers. It was developed by DuPont and consists of high-density polyethylene fibers that are processed into a non-woven fabric.

Tyvek’s composition consists of polyethylene fibers that are thermally fused into a high-density fabric. This creates a material that is resistant to tears, punctures and moisture. Tyvek is also chemically resistant to many acids, bases and solvents.

Application

Tyvek has a wide range of applications. Due to its unique properties, it is used in various industries. Tyvek is often used as a durable packaging material for shipping sensitive or fragile items. It is also used in the construction industry to create temporary or permanent protective coverings, vapor barriers, siding and insulation materials. Tyvek is used in the medical industry for sterilizable packaging, protective clothing, surgical gowns and drapes. It is also used in the apparel industry for protective clothing, work coveralls and outdoor clothing.

Benefits

The benefit of Tyvek lies in its unique properties. It is lightweight yet extremely tear resistant, which ensures long-lasting durability and hard-wearing performance. Tyvek is water resistant and breathable, keeping moisture out but still allowing water vapor to escape. It also provides a good barrier effect against dust, dirt, microorganisms and chemicals. Tyvek is recyclable and has a low environmental impact compared to other materials.

Türkçe

Türkçe Deutsch

Deutsch